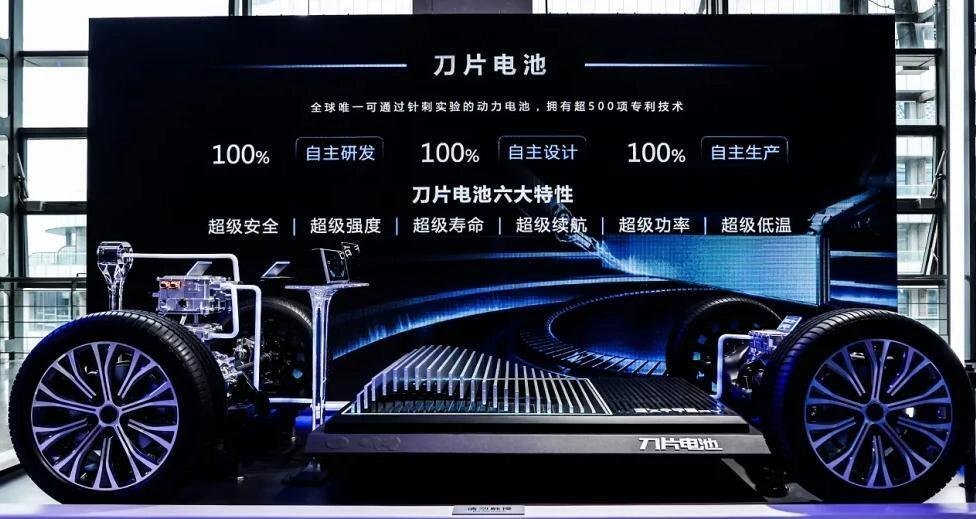

Perhaps you have heard the introduction of BYD’s Blade Battery in a certain car review video or a BYD dealership.So, what exactly is BYD’s Blade Battery and is it good enough?

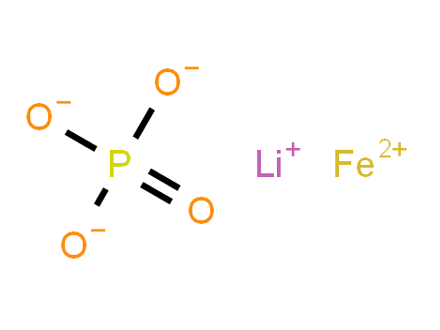

The biggest feature of the Blade Battery is safety. BYD blade batteries uses lithium iron phosphate(LFP) as the cathode material and adopts a large-size laminated process to form the flat cells into the Blade Battery pack, combined with its own CTB (Cell To Battery) battery and vehicle body integration technology. And after undergoing various strict nail penetration tests, Such Battery stands out in terms of safety.

Power batteries are one of the core components of electric vehicles, directly affecting the vehicle’s cruising range, safety, etc. And Wang Chuanfu, the chairman of BYD, has emphasized on many public occasions that BYD does not blindly pursue the energy density and performance of the battery. Ensuring the safety of the battery is the greatest comfort for consumers, and this is also the correct development path for electric vehicles.

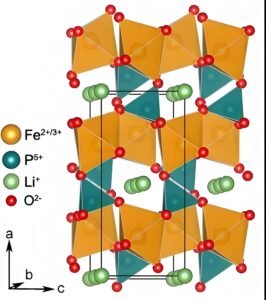

Materials:Why is Lithium Iron Phosphate(LFP)?

Because the crystal structure of lithium iron phosphate is relatively stable, and its chemical bond strength is high, especially the P-O bond is stable and not easy to decompose under high temperature conditions. This makes the battery less prone to thermal runaway in high-temperature environments, reducing the risk of fire and explosion.

Compared with another most common ternary lithium battery on the market, the differences between the two are mainly as follows:

1.Energy Density: The biggest disadvantage of lithium iron phosphate batteries is that their energy density is lower than that of ternary lithium batteries. The energy density of a single lithium iron phosphate battery cell is 180 Wh/kg, while that of NCM (Nickel Cobalt Manganese) lithium is over 250 Wh/kg. However, for the overall battery pack, BYD’s Blade Battery optimizes the shape of battery cells and adopts the module-free concept for development. It uses hard-shell long battery cells shaped like blades, omits the steps of assembling modules, and directly installs the battery cells in the battery pack, maximizing the overall energy density of the lithium iron phosphate Blade Battery.

2.Manufacturing Cost: Lithium iron phosphate has an advantage in manufacturing cost. For the same battery pack, it is about 3,000 USD cheaper than ternary lithium batteries. Lithium iron phosphate batteries are also more commonly used in mid-to-low-end vehicles, while ternary lithium requires elements such as cobalt and nickel as cathode materials since we know that cobalt is difficult to mine and has a relatively high cost. And It is mainly used in mid-to-high-end electric vehicles.

3. Service Life: Without considering other influences such as the battery management system and temperature, another advantage of lithium iron phosphate is its high battery cycle life. Theoretically, it can be recycled for more than 2,000 times, while ternary lithium batteries have a maximum of only about 1,500 – 2,000 times.

4. Safety: The greatest advantage of lithium iron phosphate lies in its higher safety. When ternary lithium is short-circuited, it will self-release heat of more than 500 joules per gram, while lithium iron phosphate is less than 150 joules per gram. Lithium releases oxygen during the combustion process while lithium iron phosphate does not.

The comparison Table between LFP vs. Ternary lithium

| lithium iron phosphate | ternary lithium(NCM) | |

| Energy Density | 140-170wh/kg | 240-300wh/kg |

| Safety | High | Normal |

| Low-temperature performance | Low | High |

| Charge and discharge performance | Normal | High |

| Cycle life | Over 2000 times | 1500-2000 times |

| Manufacturing Cost | Low | High |

Why Uses Blade Structure?

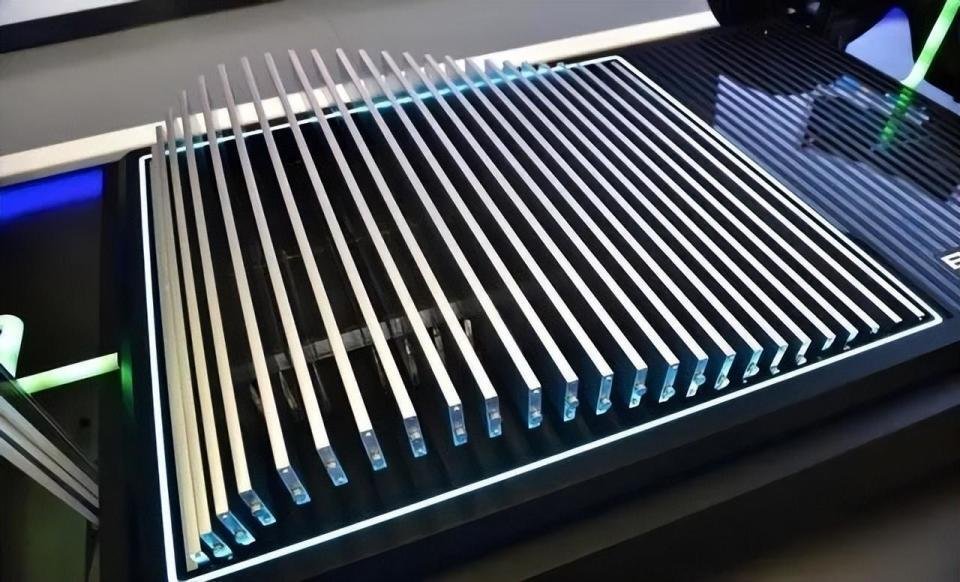

1. Shape: The basic structure of BYD’s Blade Battery belongs to the square battery. Its shape is very much like a blade, flat and long. By reducing the thickness of the battery cell and increasing the length of the battery cell, the battery cell is designed to be flat and long and thinned.

2.Packaging Method: In terms of the packaging method, the Blade Battery adopts a laminated design process. The positive electrode sheet, negative electrode sheet and separator are cut into the specified size. Then, the positive electrode sheet, separator and negative electrode sheet are laminated to form small battery cell monomers, and the small battery cell monomers are stacked and connected in parallel to form large battery cells. Then, components such as the cover plate, side plate and spacer ring are assembled and cased.

Compared with the conventional winding core process, such a laminated method can make the battery cells thinner and longer, thereby improving the space utilization rate of the battery pack and increasing the energy density.

3. Integration: Traditional batteries require modules to fit individual batteries in the battery pack, and the modules themselves occupy space in the battery pack. However, BYD Blade Battery is not in the traditional module way. The integration method of BYD Blade Battery skips the “module” link and greatly improves the volume utilization rate. Specifically, it can reduce the number of components by about 36%, increase the space utilization rate by about 98%, and increase the structural strength by about 30%. This is what BYD called CTP(Cell To Packaging Technology).

During the integration process, both ends of the battery cell are fixed on the end plates, and the support for the battery cells is provided by the frames at both ends. Support blocks and buffer side plates are designed on the tray to provide the preload force of the battery cells. This design, on the one hand, improves the overall space utilization rate of the battery pack and increases the energy density; on the other hand, since the battery cells have a larger heat dissipation area, more heat can be conducted from the inside to the outside, which can match the higher energy density, enabling the energy density of the entire volume to reach 150 kw/kg.

This performance is no worse than the performance of many mainstream ternary lithium batteries. In 2023, through the winter range tests of BYD Han EV and BYD Seal equipped with Blade Batteries, the actual range performance of the two vehicles exceeded that of many mainstream ternary lithium batteries, confirming that the energy density of the Blade Battery pack is not inferior to that of some ternary lithium batteries. In simple terms, BYD has improved the volumetric energy density of the entire battery pack by optimizing the structure and maximizing the space utilization rate.

How exactly does it perform in safety tests?

1.Puncture Experiment: When it comes to the safety of Blade Batteries, how exactly does the performance of Blade Batteries look like? In China, both BYD officials or other car review programs have conducted similar simulation experiments, that is, a puncture comparison experiment was carried out on three types of batteries: lithium iron phosphate, BYD Blade Battery and ternary lithium.

The results showed that the ternary lithium battery directly had the phenomenon of smoking, fire and explosion. The lithium iron phosphate battery only had the phenomenon of smoking. However, the Blade Battery only had concave deformation due to puncture, without smoking or fire, and the temperature only rose by 4.5 degrees Celsius.

Why is this? When the steel needle pierces the inside of the Blade Battery, it will cause a short circuit between the positive and negative electrodes. The thinner the battery, the fewer the electrode layers of the short circuit, and the lower the heat generated during the short circuit process. At the same time, the sheet-like structure also increases the heat dissipation area of the battery. Before the battery reaches the high-temperature critical point, the heat has been widely dispersed and it is not easy to catch fire.

2. Vehicle Collision Experiment: BYD adopts the CTB battery-chassis integrated structure, the Blade Battery pack is both an energy body and a structural component. And because the Blade Battery cells are closely arranged in the chassis, it is equivalent to adding a row of longitudinal beams to the vehicle, greatly improving the torsional stiffness of the vehicle body and reducing the possibility of vehicle deformation caused by external forces.

In BYD’s official claims the CTB torsional stiffness can reach 40,000+ N.m. For electric vehicles during driving, if a collision occurs, the battery pack usually suffers from extrusion by foreign objects. Under extreme conditions, it may cause an internal short circuit of the battery, thereby triggering thermal runaway. In the experiment with the BYD Seal model as the test, after two consecutive side collision tests, the staff removed the battery pack after the collision and installed it in another Seal vehicle, and the vehicle could still continue to drive. It can be seen that the torsional stiffness of CTB makes the entire vehicle body safe enough.

Are there any drawbacks of the blade batteries?

Of course, this generation of Blade Batteries is not a perfect battery. Its inherent drawbacks are the low monomer energy density, which is caused by the material characteristics as mentioned earlier.

Secondly, its low-temperature performance is not ideal. Under zero-degree conditions and without any thermal management conditions, the effective range of LFP is only 58% of that of ternary lithium batteries. Under minus 10 degrees, it may be even lower.

However, with the launch of BYD’s second-generation Blade Batteries, BYD will make further innovations in materials, such as using new positive electrode materials, such as lithium manganese iron phosphate, to improve the energy density and charge-discharge rate performance of the battery cells. The electrochemical performance under low-temperature conditions is also better. At the same time, optimizations and upgrades have been made to the pole column design, battery pack arrangement, packaging method, battery weight and volume. The cruising range is expected to exceed 1,000 km.

What cars are currently equipped with Blade Batteries?

Currently, Blade Batteries are equipped in BYD cars such as Seal, Seal-U (Song Plus EV), Qin, Han and the high-end electric sports car Yangwang U9.

Who else are currently working on blade battery technology?

Besides BYD, another Chinese automaker, Geely, is also conducting research and development on blade battery technology.

In 2024, Geely’s independently developed new generation “blade-type” lithium iron phosphate battery – the Shield Short Blade Battery was officially released. This battery has 192Wh/kg of energy density and over 3500 times cycle uses and will be the first to be installed in the launched Geely Galaxy E5.

Conclusion

At present, there is no perfect battery on the market. More and more automobile manufacturers are participating in the research of development and innovation of batteries, promoting the integration of batteries and vehicle bodies, such as BYD, Tesla, Volkswagen, and Great Wall Motor, instead of simply leaving the battery solutions to battery suppliers to solve. This is a positive and responsible attitude towards consumers.

We can be sure that when this article was written, more new battery technology were taking place. What we really want to talk about is not just a single battery technology, but we indeed hope that everyone can see the bottom-line of electric vehicle manufacturers such as BYD regarding consumer‘s safety, and at the same time, they are also on the way of pursuing the two-way development of safety and high performance of the future batteries.